While there’s no official limitations on how high you can stack pallets, OSHA standard 1910.159(c)(10) tells us that “the minimum vertical clearance between sprinklers and the material below shall be 18 inches.” Allow the ceiling to be your guide as you master pallet stacking. The materials being stacked can also affect the height limit because some have specific requirements. They also depend on the stacking technique used.

#Pallet stacking software full

However, height limits can vary according to whether the pallets are full or empty. We’ve also answered some of the most frequently asked questions about pallet stacking guidelines below: How Many Pallets Can You Safely Stack?Įxceeding the recommended height limit makes pallet stacks more prone to tip-over and collapsing. Still feeling unsure about pallet stacking ? Check out this video for additional guidance. If you’re unsure about handling a double-stacked pallet, consult with your job site manager or safety expert. Using plastic wrapping and banding can lower the risk of accidents by keeping pallets secure.

#Pallet stacking software drivers

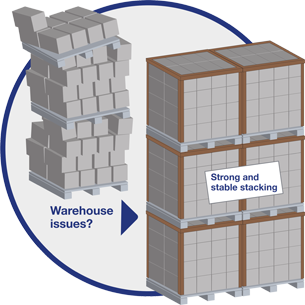

When in doubt, do the right thing and buy replacement pallets rather than using damaged ones.įorklift drivers should understand that double-stacked pallets create unique safety hazards, and should always be handled with extra caution. Any part of the pallet that contains splintered areas or protruding nails and fasteners can injure workers. Using them could lead to stack tip-overs. Damaged pallets aren’t very stable or durable. It can be tempting to reuse damaged pallets to save a few dollars here and there, but it’s a bad idea for a number of reasons.

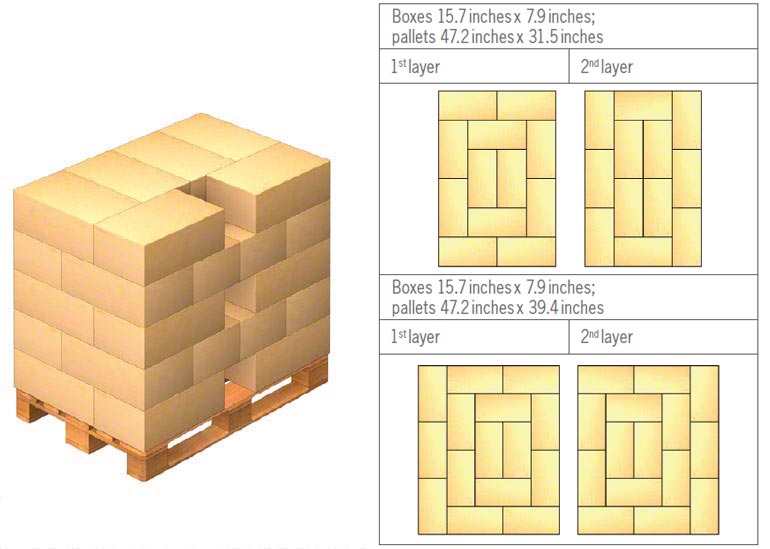

An overloaded forklift can cause an accident before the pallets are even stacked. When hauling double-stacked pallets, make sure the load doesn’t exceed the forklift’s max weight limit. This will create a stable base with a lower center of gravity. Then put the heaviest pallets on the bottom of the stack. The proper pallet stacking safety technique is to put the heaviest item(s) on the bottom of the pallet. Should the lift topple over, it can injure the operator or crush workers nearby. Lifting more than the forklift is designed to hold is a major safety hazard. Make sure you know the maximum weight the pallet jack or forklift can hold. When it comes to pallet stacking, weight limits are just as important as height limits. This kind of calculation will become second nature after a while. It’ll help you assess just how many more pallets will fit in the area. With this in mind, make sure you know how much space you have on lower and middle racks. When using a forklift to stack pallets, avoid stacking them too high – it’s incredibly dangerous and just asking for an accident to occur. Keep the following tips in mind as you perfect the art of stacking: Keep Height Limitations in Mind Of course, these principles are really just the beginning of pallet stacking guidelines. The more variation in your pallet configuration, the greater the odds of an accident. Always ensure double-stacked pallets are the same width. Stacking uniform shapes and sizes is best, as there are fewer chances for pallets to shift or fall. Start by placing the largest pallet on the bottom. Even stacking is also more space efficient, ensuring that every square inch of a space is used to its fullest capacity. This reduces the odds of pallet stacks shifting or falling over.

#Pallet stacking software how to

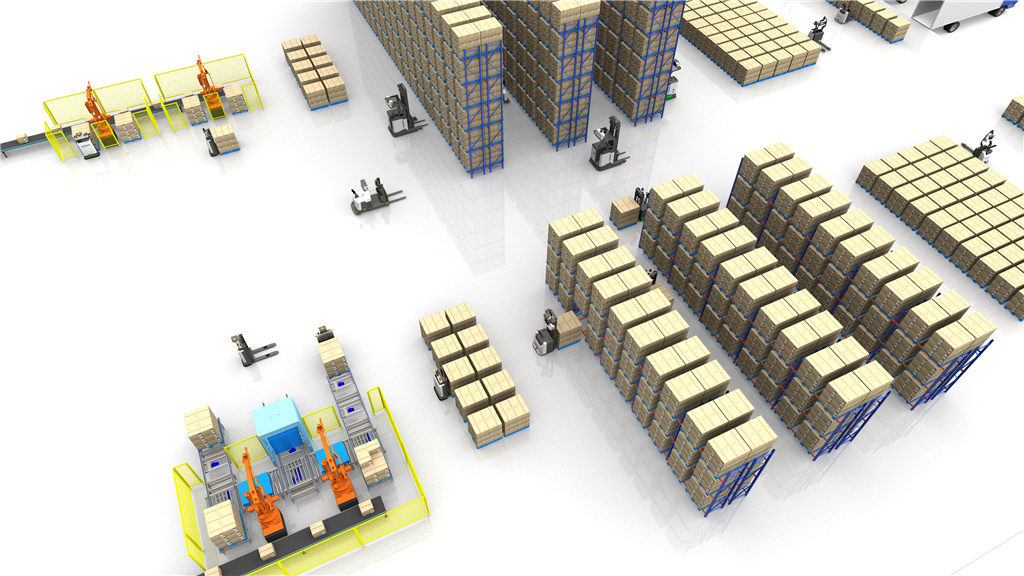

How to Safely Stack PalletsĮven distribution is the key to safe pallet stacking with forklifts. If you’re eager to learn how to stack a pallet, tips from can help. Mastering this art can improve workplace safety while also cutting costs and boosting productivity.

Five Pallet Stacking Tips You Should Know

0 kommentar(er)

0 kommentar(er)